Arcos manual machines, cleaners, polishers, grinders, allow the user to work any type of piece and material to achieve the required degree of finish. Arcos was founded in 1965 for the production of manual finishing machines and was soon recognized worldwide as a leading and reliable manufacturer. To date, Arcos are still counted among the most robust, reliable and long-lasting manual machines.

FEATURES

One of the main advantages of Arcos manual machines is that they have an extremely low vibration value, below the limit set by law. This allows operators to work in total safety. To achieve this result, important changes have been made to Arcos manual machines. Click here to learn more.

Arcos manual cleaners and grinders have the following characteristics:

Download Manual Machines Brochure

PLEASE CONTACT US HERE TO DISCUSS YOUR PROJECT

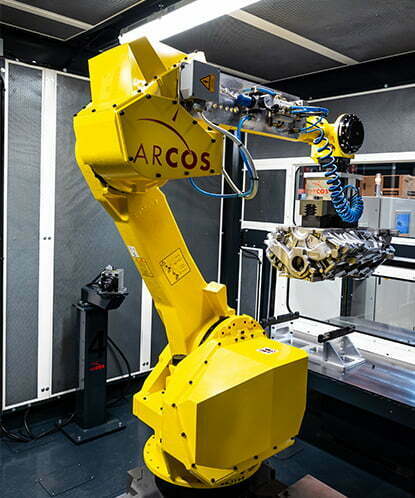

AUTOMATE YOUR MANUAL PROCESS

ROBOTIC SYSTEMS

Robotic work cells for surface finishing. Polishing, deburring and much more: Perfect for literally any material. The extreme simplicity of use and versatility have made robotic systems the best answer for every finishing problem.

CONTINUOUS ROTARY TABLES

Continuous revolving tables for polishing. An ideal solution in the case of production of many pieces, with simple and symmetrical shapes like rosettes, cylinders, knobs, handles etc.

INDEXED-CNC ROTARY TABLES

Snapping rotary table and CNC for polishing . Ideal machine for large quantities and for processing of pots, cookware, flat buckles, lids etc. With the introduction of CNC it is possible to combine high productivity even with medium-complex pieces.

CENTERLESS MACHINES

Centreless machines for polishing and grinding. Ideal solutions for surface finishing of tubes or circular section bars.

FLAT SURFACE MACHINES

Flat machines for polishing and grinding. Ideal solutions for surface finishing of slabs or flat elements of varying width and length.